中古機械磨床

-

附加 4米*1.2米電磁盤年份:1993年 行程:4M*1.5M

-

已售出!

-

日本住友龍門磨床日本住友龍門磨床

-

建德 平面磨床 500X1000 品牌:建德 型�

-

中古機械精密成型平面研磨機 SG-8040 CNC控制驅動的數控磨床 平面

研磨整合事業

-

研磨應用全方位整合團隊我們技術依賴.雙平面研磨.各種類研磨全方位整合團隊

-

-

CNC立式圓盤專用磨床-研磨技術整合CNC8軸�

-

磨輪研磨專用機團隊擁有高精密、�

-

- 高速、省電、高效率日本磨床系列: 岡本OKAMOTO

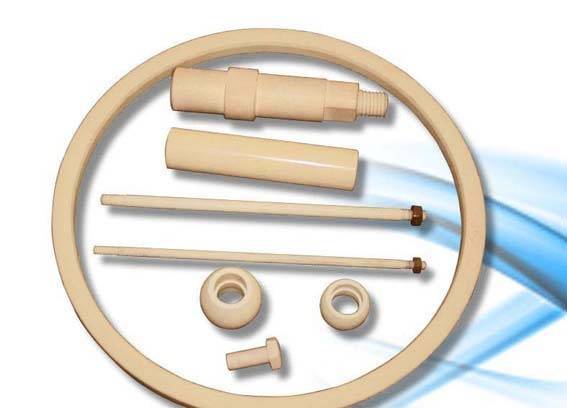

砂輪耗材專區 » 陶瓷全系列

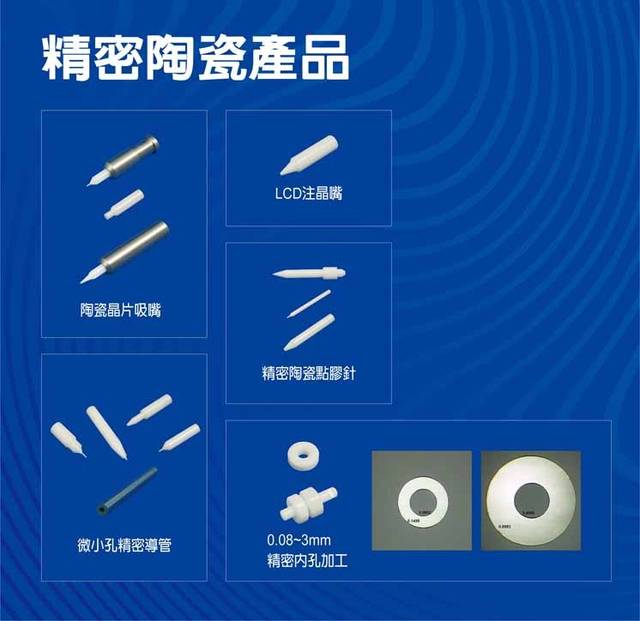

陶瓷全系列-各種精密陶瓷.套圈.套筒.陶瓷刀具.電動理髮剪刀片.陶瓷刀.軸承.適用於外圓.圓筒.外徑磨床。

Workpieces:

Crystals, Ceramics, Ferrite, Piezoelectric Elements,Carbon, Metal, Super-Hard Materials, Glass, Copy Mirrors, Photomask, LCD Glass, Glass Disks, Hard Disks, Aluminum Parts, Aluminum Disks, High Precision Aluminum Parts, Silicon Wafers, Oxide Wafers, Compound Wafers

Semiconductor Piezoelectric Elements, Super-Hard Materials, Etc.

在當前消費性電子產品快速發展的市場內,許多高科技產品的組成中,更為關鍵的是精密機構零件的支持。如高速硬碟中的Bearing、定位機構。光纖通訊中的Ceramic Ferrule、Fiber。半導體製程中的諸多治具、Bonding capillary、高級鐘錶內的齒輪機構、Jewels Bearing等等,皆需要具備精密加工技術及量產經驗來進行產品製程的規劃。但生產此類產品通常需導入歐日先進工業國家高價的製程技術及量產設備。在技術發展的自主性及成本上多所牽制。

我們憑藉過去多年在超精密產品加工(次微米公差)的領域中進行產品開發、製程測試、自動化設備開發、導入量產、實施ISO標準及客戶互動技術服務的實務經驗中,針對超精密零件的尺寸及幾何加工可為您提供製程、量產設備及檢測規劃服務、協助您快速準確的發展利基產品,節省您的開發時間及成本。

========請參考我們針對各種尺寸及幾何加工製程的實務經驗及設備介紹

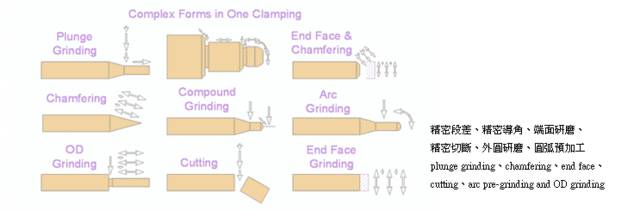

Multi-Purpose Plunge Grinder. A revolutionary grinding equipment of cylindrical grinding machine for grinding complex forms in the size range from Φ0.5mm to Φ10mm with high accuracy geometry and minimum tolerance of size. Besides, It can maximum grinding 8 surface in one clamping that includes plunge grinding、cutting、arc、end face、chamfering and OD grinding process!!

The EMPG is designed for the blank preparation machining of precision cutting tools and punch pins. It uses the V block & pressure finger to keep perfect blank geometry. Featured, rough and finish grinding could be completed with different grinding wheels in one clamping. End face grinding and chamfering could be finished in one process too.

EMPG equipped with the reliable automatic loading-unloading system. This system uses FESTO products, the top pneumatic unit from Germany and it has a highly friendly operator system in colored HMI which can be learned quickly! Spindle torque perception、prefect adjust of X & Y axis servo motion control etc., all kinds of the high-level designs provide users a highly efficiency, most precision products and lowest mass production cost!!

氧化鋁學名-(AI2O3)蘊藏量次於氧化矽,屬於陶瓷原料之一,在氧化物中鋁與氧有強力的鍵結,氧化鋁在氧化物中HK2380硬度以上,化學穩定性高且對大部份酸性、鹼性、鹽類及熔融溶液有優秀的耐腐蝕性,氧化鋁的強度受到密度及微結構影響,在常溫時強度是最高,隨著溫度升高至1000˚C時其強度明顯下降,氧化鋁也有較低的熱膨脹係數。

氧化鋁的各種特性(包含熱性質、機械性質及物理化學性質等)皆與其純度有關, 一般而言氧化鋁純度越高其導熱性質越高,且當純度極高的氧化鋁其密度接近理論密度,其機械性質越好。

近年氧化鋁以大量取代金屬等零件,改善金屬容易鏽蝕、耐磨性不佳、強度不夠容易變形及不耐高溫等較差性質,現今不僅僅是高科技的半導體業使用氧化鋁陶瓷元件,其他行業為了改善產品、提高效能及降低成本等,也漸漸改用氧化鋁陶瓷元件。.

碳化矽具有比一般陶瓷還要良好的硬度、耐熱性、耐氧化性、耐腐蝕性及高導熱性,所以近年碳化矽被廣泛應用在機械工程中的結構件和化學工程中的密封件等,甚至運用在強酸、強鹼、高磨耗、高溫、航太等極端條件的環境。

氧化鋯除了具有精密陶瓷應有高強度、硬度、耐高溫、耐酸鹼腐蝕及高化學穩定性等條件,氧化鋯還具備較一般陶瓷高的堅韌性,使得氧化鋯也運用在各個工業,像是軸封軸承、切削元件、模具、汽車零件等,甚至可用於人體,像是人工髖關節當中。

- Automatic loading-unloading system. Magazine loader for the blank preparation of cutting tools and punches. X.Y. Table loader is opted for precision tools.

- Rough and finish plunge grinding in one clamping of tool blanks.

- Precision V block & pressure finger option to keep perfect blank geometry

- Collet concentricity is tunable. That could be adjusted under 2μm.

- The wheels wear of outer diameter can be compensated.

- It can maximum grinding 8 surface of complex forms in one clamping.

- Precision wheel spindle and high rigidity workhead spindle.

- Other high-level designs for the best mass production.